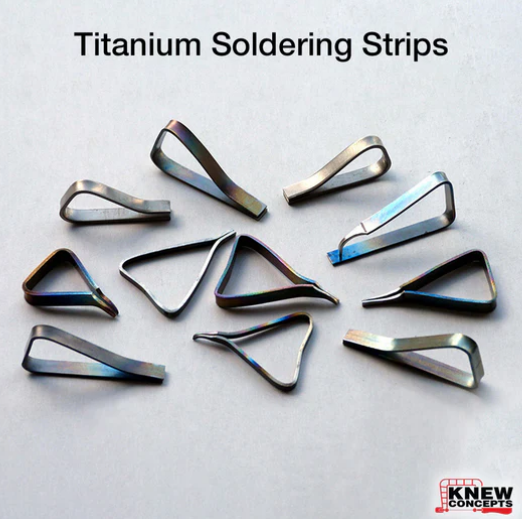

Knew Concepts Titanium Soldering Strips

Titanium has several advantages over traditional steel clamps when it comes to soldering. Solder doesn’t stick to it. Enamel doesn’t stick either. It stays strong when red hot. It doesn’t erode and flake away at heat, so your clamp tips can be smaller. Most importantly, titanium doesn’t transfer heat nearly as quickly as steel clamps, so it interferes with nearby joints less than steel clamps do.

These clamps are sold in a pack of 10 “blanks” as straight 10.16cm strips, to allow you to bend your own ideal clamp designs. Each soldering situation is different, and while there are a few basic designs that we illustrate in the how to bend and shape clamp instructions, every jeweller is different, and each solders in their own unique way, and will need clamps customized for their own personal style, or unique need. The titanium strips are fully annealed, and can be bent and filed to suit in minutes.

To date, we’ve found several uses for them:

holding ear wires during soldering

holding bails and jump rings

re-setting sweat soldered panels that had warped during the first soldering

clamping several items together during soldering

soldering hemispheres into a full sphere

holding spheres onto ring shanks

the list will go on...

Titanium has several advantages over traditional steel clamps when it comes to soldering. Solder doesn’t stick to it. Enamel doesn’t stick either. It stays strong when red hot. It doesn’t erode and flake away at heat, so your clamp tips can be smaller. Most importantly, titanium doesn’t transfer heat nearly as quickly as steel clamps, so it interferes with nearby joints less than steel clamps do.

These clamps are sold in a pack of 10 “blanks” as straight 10.16cm strips, to allow you to bend your own ideal clamp designs. Each soldering situation is different, and while there are a few basic designs that we illustrate in the how to bend and shape clamp instructions, every jeweller is different, and each solders in their own unique way, and will need clamps customized for their own personal style, or unique need. The titanium strips are fully annealed, and can be bent and filed to suit in minutes.

To date, we’ve found several uses for them:

holding ear wires during soldering

holding bails and jump rings

re-setting sweat soldered panels that had warped during the first soldering

clamping several items together during soldering

soldering hemispheres into a full sphere

holding spheres onto ring shanks

the list will go on...

Titanium has several advantages over traditional steel clamps when it comes to soldering. Solder doesn’t stick to it. Enamel doesn’t stick either. It stays strong when red hot. It doesn’t erode and flake away at heat, so your clamp tips can be smaller. Most importantly, titanium doesn’t transfer heat nearly as quickly as steel clamps, so it interferes with nearby joints less than steel clamps do.

These clamps are sold in a pack of 10 “blanks” as straight 10.16cm strips, to allow you to bend your own ideal clamp designs. Each soldering situation is different, and while there are a few basic designs that we illustrate in the how to bend and shape clamp instructions, every jeweller is different, and each solders in their own unique way, and will need clamps customized for their own personal style, or unique need. The titanium strips are fully annealed, and can be bent and filed to suit in minutes.

To date, we’ve found several uses for them:

holding ear wires during soldering

holding bails and jump rings

re-setting sweat soldered panels that had warped during the first soldering

clamping several items together during soldering

soldering hemispheres into a full sphere

holding spheres onto ring shanks

the list will go on...